Automated intralogistics with automated guided vehicles - the future of automated logistics

You are familiar with the challenges of your industry – time pressure, high efficiency requirements and the demand for top performance are omnipresent. However, problems such as staff shortages, rising costs and a lack of automation expertise can jeopardize success. Automated logistics offers a solution here: automated guided vehicles (AGVs) enable efficient and scalable optimization of your intralogistics processes. With AGV logistics, you create clear competitive advantages through precise, continuous material flows and reduced manual intervention.

AGV logistics: AGVs as part of a high-performance AGV in automated logistics

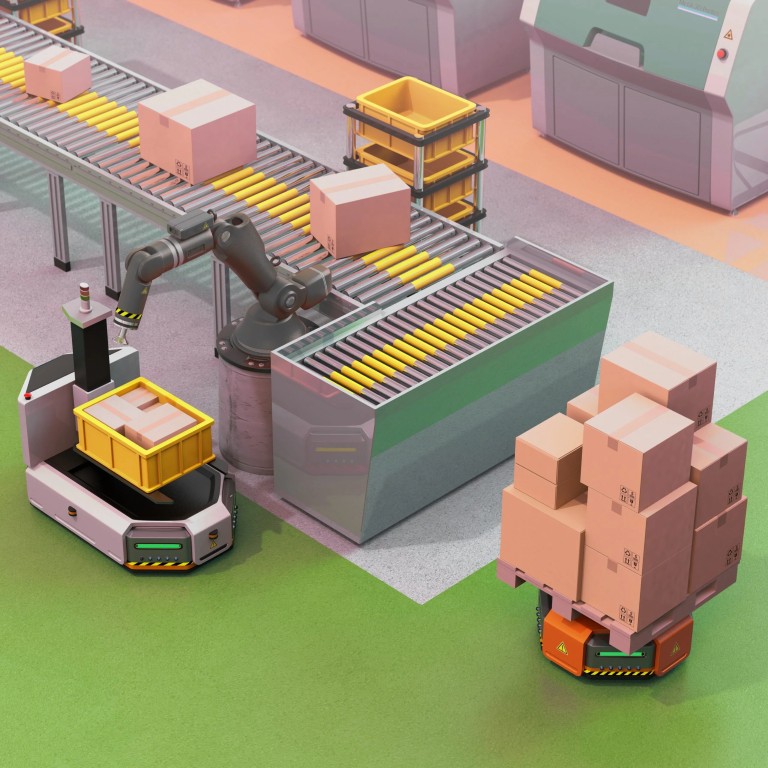

Automated guided vehicles (AGVs) are automated conveyor systems that are primarily designed to move materials in production and logistics processes. They are a central element of automated logistics, as they not only perform transportation tasks, but can also be flexibly integrated into existing systems. A typical feature of AGV logistics is ground-based transportation using automated guided vehicles (AGVs). These vehicles transport goods of different sizes, masses and shapes along a defined network of routes – from standardized transport crates and pallets to complex components and complete workstations.

Roadmap for the successful implementation of an AGV project

Advantages of automated guided vehicles - AGVs

By eliminating drivers and reducing errors and accidents, operating costs can be significantly reduced. With conventional logistics vehicles, 80% of the costs are attributable to personnel alone.

Self-driving vehicles enable continuous operation around the clock. By automating intralogistics, material flows are made more efficient, which significantly increases handling capacity.

FAQ - Frequently asked questions about automated guided vehicle systems AGVs

What is an automated guided vehicle system? (AGV)

Automated guided vehicles (AGVs) consist of one or more driverless transport vehicles (AGVs) that operate on fixed routes under central control and are designed for predefined tasks in stable environments. In contrast, autonomous mobile robots (AMR) navigate flexibly and intelligently in dynamic environments by using sensors and artificial intelligence. While AGVs offer less flexibility, AMRs can automatically adapt to changes and work efficiently in real time.

What is the difference between autonomous mobile robots (AMR), AGVs and AGVs?

Automated guided vehicles (AGVs) consist of one or more automated guided vehicles (AGVs) and operate on fixed routes with centralized control and are suitable for predefined tasks in stable environments, while autonomous mobile robots (AMRs) navigate flexibly and intelligently in dynamic environments by using sensor technology and artificial intelligence. AGVs offer less flexibility, while AMRs can automatically adapt to changes and work efficiently in real time.

What different AGVs are there?

Automated guided vehicle systems (AGVs) consist of one or a variety of automated guided vehicles (AGVs) such as fork-lift AGVs, piggyback AGVs, tugger train AGVs, underride AGVs, assembly AGVs, heavy-duty AGVs, mini AGVs, outdoor AGVs or special AGVs, which are designed for different transportation requirements in logistics and production.

What advantages do AGVs offer?

These systems are characterized by a high degree of scalability, which is achieved by expanding the number of automated guided vehicles (AGVs) and transfer stations. They also offer the option of implementing layout changes. They are ideal for adapting to fluctuations in dynamic material flows and enable the safe and reliable transportation of almost all conveyed goods by adapting the load handling device.

Are automated guided vehicles safe?

Automated guided vehicles (AGVs) are characterized by a high level of safety, as they are equipped with advanced sensors, real-time monitoring, emergency shutdowns and intelligent route planning to prevent collisions and ensure consistent performance.

What applications are AGVs suitable for?

Automated guided vehicles (AGVs) are ideal for use in areas such as warehousing, logistics, production, hospitals, airports, retail and various industries. In principle, they can be used anywhere where transportation tasks regularly occur.

Which AGV is best suited to my application?

We can discuss your requirements in a personal consultation and in the AGV basic check we will show you whether the system is technically feasible and economically viable. You can also take a look at our white papers, which provide you with valuable knowledge about AGV projects.

Components of automated guided vehicle systems in intralogistics

Automated guided vehicle systems consist of one or more automated guided vehicles (AGVs), a control system, a location determination system, a data transmission system and the infrastructure with peripheral equipment. These are important factors in automated logistics and enable a seamless, efficient material flow – without any manual intervention.

An automated guided vehicle (AGV) essentially consists of a chassis, a computer, one or more drive(s), the power supply, a load handling module, a communication module, a safety component and a user interface. Thanks to their modular design and precise adaptation to the respective operating conditions, AGVs can be flexibly integrated into existing automated logistics processes.

If you would like to find out more about automated guided vehicle systems, we recommend our AGV basic training or our free white papers.

AGV Logistics

The benefits of AGV logistics systems at a glance:

Tailored to individual requirements: AGVs can be used flexibly and can be adapted to changes in intralogistics.

As AGVs perform heavy and repetitive tasks in intralogistics, they reduce physical strain and the risk of injury for human workers

AGVs are able to work around the clock, which significantly shortens throughput times.

Although the initial investment can be high, AGVs reduce operating costs in the long term.

AGVs are equipped with sensors and advanced safety systems that prevent accidents and collisions.

AGVs are often integrated into digital systems that enable real-time monitoring and tracking of materials and products.

Experts Team

Satisfied customers

Projects

Arrange your AGV consultation

Our dedicated team of experts will be happy to help you further Your request is our mission to provide you with excellent service.

We look forward to your message.

Make an appointment directly

Our AGV and AMR expert Felix Imhof is available to answer any questions you may have about your AGV project.