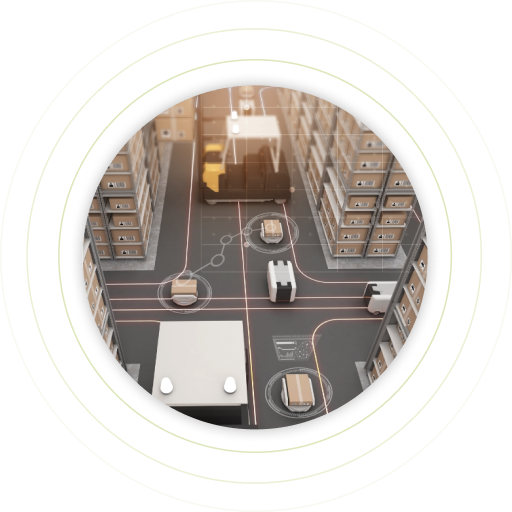

Rethinking logistics - into the future with autonomous forklift trucks

Automate your intralogistics. Flexible, safe, efficient. A shortage of skilled workers, increasing cost pressure and high efficiency requirements are shaping logistics. Autonomous forklift trucks offer a decisive advantage here: they take the pressure off existing teams, reduce operating costs and ensure stable, scalable processes – even with growing order volumes.

Autonomous forklift trucks

Autonomous forklift trucks are automated industrial trucks that independently pick up, transport and set down pallets, pallet cages and other load carriers. They navigate through the warehouse or production environment with the help of sensors, cameras and intelligent control systems – without human intervention.

A typical feature of autonomous forklift trucks is the combination of precise navigation, automatic load handling and high flexibility when used in existing infrastructures. They are suitable for both standardized transport tasks and complex internal material flows and can be seamlessly integrated into modern logistics and automation processes.

Advantages of autonomous forklift trucks

By eliminating drivers and reducing errors and accidents, operating costs can be lowered. With conventional logistics vehicles, 80% of costs are accounted for by personnel costs alone.

Self-propelled forklifts can be used around the clock. Material flows are optimized through automation, which significantly increases handling capacity.

Autonomous forklifts reduce the risk of accidents and injuries by using automated safety protocols. As a result, costs due to damage are minimized. The AGV expert opinion provides information on the safety of a system.

FAQ - Frequently asked questions about autonomous forklift trucks

What is an autonomous forklift truck?

An autonomous forklift truck is an automated industrial truck that carries out transportation, storage and retrieval processes within a company independently – without any manual intervention. These vehicles use modern sensor technology, cameras and navigation systems to detect their surroundings and navigate safely through storage or production areas. Among other things, these systems use autonomous forklift trucks, also known as

Automated guided vehicles (AGVs) that use various navigation and control technologies.

What are the advantages of autonomous forklifts?

Autonomous forklifts enable flexible and efficient automation of in-house transportation processes. They reduce manual intervention, lower operating costs and increase process reliability. Thanks to their sensor-based navigation, they move safely in mixed traffic and react reliably to changes in the environment. In addition, the systems can be expanded on a modular basis and enable step-by-step integration into existing logistics structures.

Are autonomous forklift trucks safe?

Autonomous forklift trucks are safe because they are equipped with advanced sensor technology, intelligent environment monitoring, emergency stop functions and dynamic route planning. These technologies enable reliable collision avoidance and ensure trouble-free operation in the ongoing logistics process.

What applications are autonomous forklifts suitable for?

Autonomous forklifts are ideal for use in warehousing, logistics, production, retail and various industrial environments. They can be used wherever pallets or other transport goods need to be moved regularly – efficiently, reliably and automatically.

Which autonomous forklift truck is best suited to my application?

We can discuss your requirements in a personal consultation and in the AGV basic check we will show you whether the system is technically feasible and economically viable. You can also take a look at our white papers, which provide you with valuable knowledge about AGV projects.

How quickly does a system with autonomous forklift trucks pay for itself (ROI)?

The return on investment (ROI) for a system with autonomous forklift trucks in intralogistics depends on various factors – including the number of forklift trucks used, the current degree of automation of the material flow, the existing infrastructure and local labor costs. In many applications, automated forklift solutions pay for themselves within 2 to 4 years.

A system check for feasibility with the AGV basic check analyzes these influencing variables in detail. In addition to direct cost savings through reduced personnel costs, autonomous forklift trucks offer additional benefits such as higher process reliability, minimized error rates and improved material availability – which has a positive impact on ROI in the long term.

How flexible are autonomous forklifts in changing production environments?

Autonomous forklift trucks are designed in such a way that they can be flexibly adapted to changing environments and processes. Route adjustments, layout changes or new transport orders can usually be implemented on the software side and without structural measures. Attention should therefore be paid to possible scaling as early as the planning stage.

Systems with free navigation in particular – such as those based on SLAM (Simultaneous Localization and Mapping) – offer a high degree of adaptability. This means that autonomous forklift trucks are not only a solution for current requirements, but also future-proof for growing or changing production and logistics processes.

Components of a system with autonomous forklift trucks

Systems with autonomous forklift trucks consist of one or more autonomous forklift trucks, a central control system, precise location determination, stable data transmission and the necessary infrastructure, including peripheral equipment.

An autonomous forklift truck essentially consists of a stable chassis, a powerful computer, one or more electric drives, the power supply (e.g. lithium-ion battery), a load handling module (e.g. forks), a communication module, safety-relevant sensors and a user interface for maintenance and diagnostics.

If you would like to find out more about autonomous forklift trucks, we recommend our basic training course on mobile robotics or our free white papers on automated intralogistics solutions.

Navigation methods for systems with autonomous forklift trucks

Choosing the right navigation method is crucial for success. ProLog Automation offers extensive expertise to ensure that navigation is optimally tailored to your requirements. Here is an overview of the most common methods:

1. physically track-bound

These cost-effective options include guide wires, magnetic tapes or colored lines. Vehicles follow a predetermined track that is precisely installed. Disadvantages include low flexibility and susceptibility to damage.

2. virtual track-based

Systems such as magnetic point/grid navigation or laser triangulation offer high accuracy and flexibility. They do not require physical tracks, but use digital maps or magnetic grids.

3. freely navigating (autonomous)

With contour navigation (SLAM), vehicles such as forklift trucks adapt dynamically to their environment. This method requires no additional infrastructure, but is susceptible to changes in the environment.

Safety concepts for systems with autonomous forklift trucks

Safety comes first! Systems with autonomous forklift trucks are equipped with state-of-the-art safety functions to ensure smooth operation and the protection of people and equipment.

Active safety systems:

- Personal protection scanner: Automatic adaptation of the safety fields to the speed of the AGV. Persons in the warning area lead to a reduction in speed or a stop.

- Ultrasonic sensors: Robust obstacle detection, insensitive to dust, moisture and ambient light.

- 3D cameras: Precise detection of obstacles such as overhanging loads or forks of other vehicles.

- Visual and acoustic warning signals: directional lights, indicators and warning beepers for maximum visibility and safety in high-traffic areas.

Passive safety systems:

- Bumpers: Mechanical bumpers that stop the trucks immediately on contact.

- Emergency stop button: Manual safety devices for a quick stop in dangerous situations.

-

We can provide you with comprehensive advice on the subject of security.

Material flow and process optimization with autonomous forklifts

Autonomous forklift truck systems consist of one or more autonomous vehicles such as forklift trucks, a central control system, precise location determination, stable data transmission and the necessary infrastructure including peripheral equipment.

At its core, an autonomous forklift truck consists of a robust chassis, a powerful computer, one or more electric drives, an energy source such as a lithium-ion battery, a load handling module (e.g. forks), a communication system, safety-related sensors and a user interface for maintenance and diagnostics.

If you would like to find out more about autonomous forklift trucks, we recommend our basic training course or our free white papers on automated intralogistics solutions.

AUTONOMOUS

FORKLIFT TRUCK

The benefits of autonomous forklift trucks at a glance:

Tailored to individual requirements: Autonomous truck systems can be used flexibly and can be adapted to changes.

As autonomous forklift trucks perform heavy and repetitive tasks, they reduce physical strain and the risk of injury for human workers.

Autonomous forklifts are able to work around the clock, which significantly reduces throughput times.

Autonomous forklifts work with constant precision and are not susceptible to human error, sick days or fatigue. This ensures high quality and stable processes in the internal material flow.

Although the initial investment can be high, systems with autonomous forklift trucks reduce operating costs in the long term.

Autonomous trucks are equipped with sensors and advanced safety systems that prevent accidents and collisions.

Autonomous forklift trucks are often integrated into digital systems that enable real-time monitoring and tracking of materials and products.

Whether individual vehicles or fleet solutions – systems with autonomous forklift trucks can be expanded on a modular basis. This allows the automation solution to grow flexibly with the company without having to replace existing systems.

Experts Team

Satisfied customers

Projects

Arrange your consultation on autonomous forklift trucks

Our dedicated team of experts will be happy to help you further Your request is our mission to provide you with excellent service.

We look forward to your message.

Make an appointment directly

Our AGV and AMR expert Felix Imhof is available to answer any questions you may have about your AGV project.