AGV robots: the future of intralogistics

With ProLog Automation you have discovered the market leader for AGV services. The meticulous work of our experts underlines our conviction that AGV robots are the future of internal logistics.

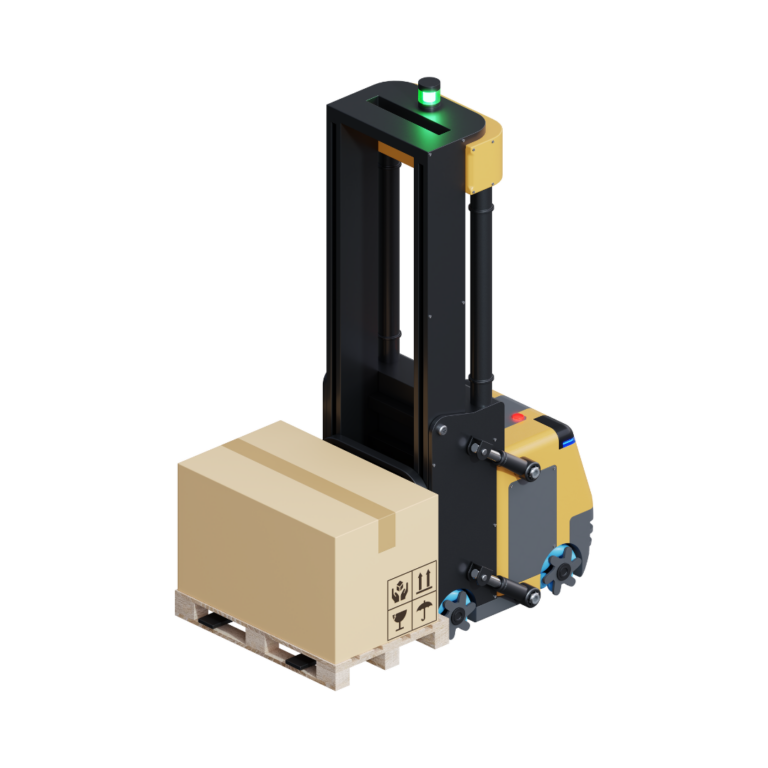

AGV robots are automated conveyor systems that are primarily used to transport materials efficiently in production and logistics processes. AGVs – Automated Guided Vehicles – are characterized by floor-bound movement along predefined routes or by dynamic navigation. They can transport goods of different sizes, masses and shapes – from standardized transport boxes and pallets to complex components and entire workstations. Thanks to their flexibility and integration into modern logistics systems, AGV robots help to optimize material flows and reduce human intervention in operations.

Advantages of AGV robots

Costs of AGV robots

By eliminating manual operation and minimizing errors and accidents, AGV robots make a significant contribution to reducing operating costs. In comparison, up to 80 % of the total costs of conventional logistics systems are accounted for by personnel expenses.

Reliability of AGV robots

AGV robots enable seamless operation around the clock. Automation ensures optimized material flows, significantly increasing handling performance and making processes more efficient.

Safety of AGV robots

AGV robots reduce the risk of accidents and injuries through advanced safety protocols. This not only leads to a safer working environment, but also to a significant reduction in costs due to damage claims. A detailed analysis of safety can be carried out by preparing an AGV report.

AGV robots as a solution

AGV robots fulfillthe highest requirements of modern industrial environments. Thanks to intelligent control, flexible application options and precise navigation, autonomous transport robots are suitable for the reliable automation of material flows and logistics processes in a wide range of industrial environments. They optimize efficiency, safety and productivity throughout the entire production process. production– and storage area.

Increased productivity through the use of AGV robots

Automated guided vehicles (AGVs) are developed in such a way that they can be flexibly adapted to the company’s individual logistics requirements. The modular architecture, high flexibility and intelligent control of AGV robots help companies to organize material flows efficiently. They can thus shorten processes and time to market in the long term.

Areas of application for AGV robots

AGVs and autonomous mobile robots (AMR) perform a wide range of intralogistics tasks such as line feeding, kitting, assembly processes and end-of-line handling. Even complex applications such as goods-to-robot (G2R), cell loading and Pallet transports are efficiently implemented by AGV robots. This sustainably increases the cost-effectiveness and efficiency of your intralogistics.

FAQ - Frequently asked questions about AGV robots

What is an AGV robot?

An AGV robot is a driverless transport robot that enables the fully automated transportation of materials and goods within a company or plant without human intervention.

What is the difference between AGV robots, AGVs and AGVs?

AGV robots consist of one or more automated guided vehicles (AGVs) that operate on defined routes and are controlled by a central control system. They are ideal for stable, predefined tasks in constant environments. In contrast, autonomous mobile robots (AMR) use advanced sensor technology and artificial intelligence to navigate flexibly and intelligently in dynamic environments. While AGVs and AGVs offer less flexibility, AMRs can automatically adapt to changes and work efficiently in real time.

What different AGV robots are there?

Automated guided vehicles (AGVs) consist of one or a variety of automated guided vehicles (AGVs) such as fork-lift AGVs, piggyback AGVs, tractor AGVs, underride AGVs, assembly AGVs, heavy-duty AGVs, mini AGVs, outdoor AGVs or special AGVs, which are designed for different transportation requirements in logistics and production.

What advantages do AGV robots offer?

AGV robots offer high scalability, as the number of vehicles and transfer stations can be easily expanded. They also enable flexible layout changes and adapt well to fluctuations in dynamic material flows. By adapting the load handling device, AGV robots can transport almost any material safely and reliably.

Are AGV robots safe?

AGV robots are safe because they are equipped with advanced sensors, real-time monitoring, emergency shutdowns and intelligent route planning to avoid collisions and ensure consistent performance.

What applications are AGV robots suitable for?

AGV robots are ideal for use in warehousing, logistics, production, hospitals, airports, retail and various industries. They can be used wherever materials or goods need to be transported on a regular basis.

Which AGV is best suited to my application?

We can discuss your specific requirements in a personal consultation and show you in the AGV basic check whether the system is technically feasible and economically viable. We also offer you the opportunity to read our white papers, which provide you with valuable knowledge about AGV projects.

How are AGV robots coordinated and controlled?

Fleets of AGVs are coordinated via a master controller: This plans routes, prioritizes orders, sends commands and receives telemetry data.

The standardized VDA 5050 interface for AGV communication (developed jointly by VDA and VDMA) is available for cross-manufacturer integration and enables mixed fleets.

Components of AGV robots

AGV robots consist of one or more autonomous transport vehicles, a master control system, a location determination system, a data transmission system and the infrastructure with peripheral equipment.

An AGV robot essentially consists of a chassis, a computer, one or more drive(s), the power supply, a load handling module, a communication module, a safety component and a user interface.

If you would like to find out more about AGV robots, we recommend our AGV basic training course or our free white papers.

Experts Team

Satisfied customers

Projects

Customer feedback on our AGV services

I was particularly impressed by the detailed documentation of their maintenance intervention with repair. Every step was carefully recorded, which not only created transparency, but also enabled us to better understand the process and build on it in the future.

AGV Maintenance

With the AGV basic check, the on-site inspection, the determination of all relevant conditions as well as analysis and the transport matrix were created. Advice on technical and economic feasibility was particularly important for us, as the ROI is not given in this area of Groz-Beckert's work.

AGV Basic Check

The service technicians who were made available to us in the current project were a fantastic fit, both in terms of their qualifications and on a personal level, very motivated and equipped with the necessary skills to provide our team with the best possible support. I would particularly like to emphasize that the structures and organization at ProLog Automation were always able to send the service technicians to Switzerland.

AGV Maintenance

The AGV training enabled us to exchange technical information, discuss open questions on the implementation of AGVs, occupational safety and legal regulations and the AGV experts Volker Single and Holger Scholz were able to develop practical solutions together with the LISTA team.

AGV Trainings

ProLog Automation has been supporting us in servicing and commissioning our automated guided vehicle systems for more than 5 years. We can always rely on ProLog's very reliable and highly trained team, with whose support we have recently successfully realized projects in Germany, Turkey, Egypt and the Netherlands.

AGV Commissioning

The topic of AGVs was new to us and we had no experience. With the AGV basic check, we were able to familiarize ourselves in detail with all the topics for an automated guided vehicle system in order to select the right manufacturer for us. Some of the highlights were the technical expertise and punctuality of the employees deployed on site. We were particularly satisfied with the reliability and clear communication during the entire course of the project.

AGV Basic Check

The practice-oriented and effective planning and advice has fully convinced us, although the desired product does not yet exist, we have a detailed and comprehensive overview with the feasibility study. I was particularly impressed by the expertise of the staff on site. We would like to emphasize the very good communication and punctuality. The schedule was always adhered to. Our idea of the service was fully realized. The next steps will follow with ProLog Automation.

AGV Basic Check

Thanks to the procedure with the FTS basic check, we have dealt with all the important questions! We were not previously aware of the extent of the criteria, such as what we need to consider in the event of a fire! The presentation of the advantages and disadvantages of the various systems was also particularly important.

AGV Basic Check

Successful training of Pramac AGV Premium Partners: Our dealers are now fit to advise on our Lifter Mobile Robotics AGV solutions! Together with ProLog Automation, we have laid the foundations for a successful collaboration. "The opportunity to see the APTIX in action directly at ProLog has ideally combined theory with practice!" We look forward to the successful implementation of many projects!

AGV Trainings

ProLog Automation is a trusted partner that supports us in our customer projects. Their extensive expertise in the field of mobile robots and their wide range of services contribute significantly to the ongoing success of our robotics ecosystem approach. This ensures first-class support for sustainable results in a variety of project scenarios - with AnyFleet, the iw.hubs and our partner robots.

AGV commissioning & AGV maintenance

"Absolutely professional and in tune with the times." The automation professionals from Neckar discussed the required points with us and implemented them in a targeted manner. During the project phase, ProLog identified other valuable aspects that contributed significantly to our success. The technical preparation was outstanding - well thought-out, precise and tailored to our needs. ProLog was flexible and customer-oriented at all times. It was the kind of collaboration you want - efficient, based on partnership and with real added value.

Rating from even-logistics.com

AGV quote review & technical evaluation

Plan your AGV robot project here.

Are you ready to unleash the potential of AGV robots for your company? Get our “AGV basic check” service! You will receive an analysis of the current situation with an on-site appointment, a feasibility assessment for the implementation of an AGV and advice on implementation. The final presentation includes recommendations on vehicle type, navigation, safety interventions, peripheral equipment and an estimate of the number of vehicles required and the total investment.

If you want to discuss how our services can optimize your business operations, contact us now.