Your customized solution for mobile robotics in logistics!

The guide to the introduction of mobile robotics for logistics managers in medium-sized companies.

Would you like to implement mobile robotics in your intralogistics? We can provide you with a professional concept directly from a manufacturer-independent mobile robotics expert. You can rely on us – we will work with you to successfully implement your intralogistics concept – without stress, without unnecessary cost surcharges and with concentrated expert knowledge from over 30 years of mobile robotics experience.

We hear two sentences again and again:

“Our logistics need to be automated, where should I even start?”

“I don’t know which supplier is right for us.”

We are at your side. This is what you get

during concept validation:

in your mobile robotics system

60+

Experts Team

243

Satisfied customers

1000

Projects

Experienced planners

“If you want to implement mobile robotics, you need a concept so that you can talk to suppliers on an equal footing.”

We promise you maximum support in the areas of concept validation, planning, service, commissioning and system operation.

Attention: You will NOT receive this from us!

- a realistic and honest statement as to whether a mobile robotics project makes sense and is feasible.

- How and with whom it can best be implemented.

Attention: This is what you will receive from us!

A partner at eye level who gives you an honest assessment and opinion from over 30 years of mobile robotics experience and is interested in the success of your project.

Content and scope of the concept validation

- Load carrier testing

- Layout and driving course recommendation

- Stations / workplaces

- Safety / Standards

- Vehicle selection

- Cost accounting

- Manufacturer selection

- Next steps

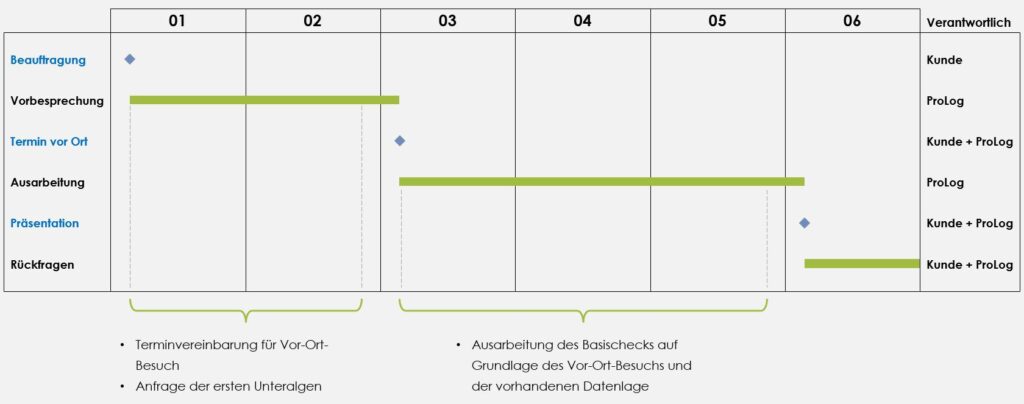

This is what you need in terms of time and resources:

- 1-2 hours kickoff meeting online incl. preparation

- 4-8 hours on-site appointment to assess your conditions, depending on the size and complexity of the system

- 1-2 hours online meeting for queries and information

- 1-2 hours for the final presentation

WHAT

OUR CUSTOMERS SAY

I was particularly impressed by the detailed documentation of their maintenance intervention with repair. Every step was carefully recorded, which not only created transparency, but also enabled us to better understand the process and build on it in the future.

AGV Maintenance

With the AGV basic check, the on-site inspection, the determination of all relevant conditions as well as analysis and the transport matrix were created. Advice on technical and economic feasibility was particularly important for us, as the ROI is not given in this area of Groz-Beckert's work.

AGV Basic Check

The service technicians who were made available to us in the current project were a fantastic fit, both in terms of their qualifications and on a personal level, very motivated and equipped with the necessary skills to provide our team with the best possible support. I would particularly like to emphasize that the structures and organization at ProLog Automation were always able to send the service technicians to Switzerland.

AGV Maintenance

The AGV training enabled us to exchange technical information, discuss open questions on the implementation of AGVs, occupational safety and legal regulations and the AGV experts Volker Single and Holger Scholz were able to develop practical solutions together with the LISTA team.

AGV Trainings

ProLog Automation has been supporting us in servicing and commissioning our automated guided vehicle systems for more than 5 years. We can always rely on ProLog's very reliable and highly trained team, with whose support we have recently successfully realized projects in Germany, Turkey, Egypt and the Netherlands.

AGV Commissioning

The topic of AGVs was new to us and we had no experience. With the AGV basic check, we were able to familiarize ourselves in detail with all the topics for an automated guided vehicle system in order to select the right manufacturer for us. Some of the highlights were the technical expertise and punctuality of the employees deployed on site. We were particularly satisfied with the reliability and clear communication during the entire course of the project.

AGV Basic Check

The practice-oriented and effective planning and advice has fully convinced us, although the desired product does not yet exist, we have a detailed and comprehensive overview with the feasibility study. I was particularly impressed by the expertise of the staff on site. We would like to emphasize the very good communication and punctuality. The schedule was always adhered to. Our idea of the service was fully realized. The next steps will follow with ProLog Automation.

AGV Basic Check

Thanks to the procedure with the FTS basic check, we have dealt with all the important questions! We were not previously aware of the extent of the criteria, such as what we need to consider in the event of a fire! The presentation of the advantages and disadvantages of the various systems was also particularly important.

AGV Basic Check

Successful training of Pramac AGV Premium Partners: Our dealers are now fit to advise on our Lifter Mobile Robotics AGV solutions! Together with ProLog Automation, we have laid the foundations for a successful collaboration. "The opportunity to see the APTIX in action directly at ProLog has ideally combined theory with practice!" We look forward to the successful implementation of many projects!

AGV Trainings

ProLog Automation is a trusted partner that supports us in our customer projects. Their extensive expertise in the field of mobile robots and their wide range of services contribute significantly to the ongoing success of our robotics ecosystem approach. This ensures first-class support for sustainable results in a variety of project scenarios - with AnyFleet, the iw.hubs and our partner robots.

AGV commissioning & AGV maintenance

"Absolutely professional and in tune with the times." The automation professionals from Neckar discussed the required points with us and implemented them in a targeted manner. During the project phase, ProLog identified other valuable aspects that contributed significantly to our success. The technical preparation was outstanding - well thought-out, precise and tailored to our needs. ProLog was flexible and customer-oriented at all times. It was the kind of collaboration you want - efficient, based on partnership and with real added value.

Rating from even-logistics.com

AGV quote review & technical evaluation

Any questions?

Click here and book a non-binding consultation at your desired time

The content and scope of the concept validation: load carrier testing, layout and route recommendation, stations / workplaces, safety / standards, vehicle selection, cost calculation, manufacturer selection, further procedure.

Yes, we not only validate whether the technical feasibility is given, with the concept validation you receive a complete basis for decision-making, an ROI calculation and also a recommendation as to which suppliers are suitable for you.

Yes, here we provide you with the most important information on flooring, fire protection, space conditions, safety, expansion joints, interfaces and much more before construction begins. The concept will save you money during the subsequent implementation.

The right time is as soon as you have the idea and a rough budget for automation.

No, we are an independent service provider and will find the right manufacturer for you in your interests.

Make an appointment directly

Our AGV and AMR expert Felix Imhof is available to answer any questions you may have about your AGV project.